White Paper – Designing & Building Sustainably: The Embodied Carbon Reality Check

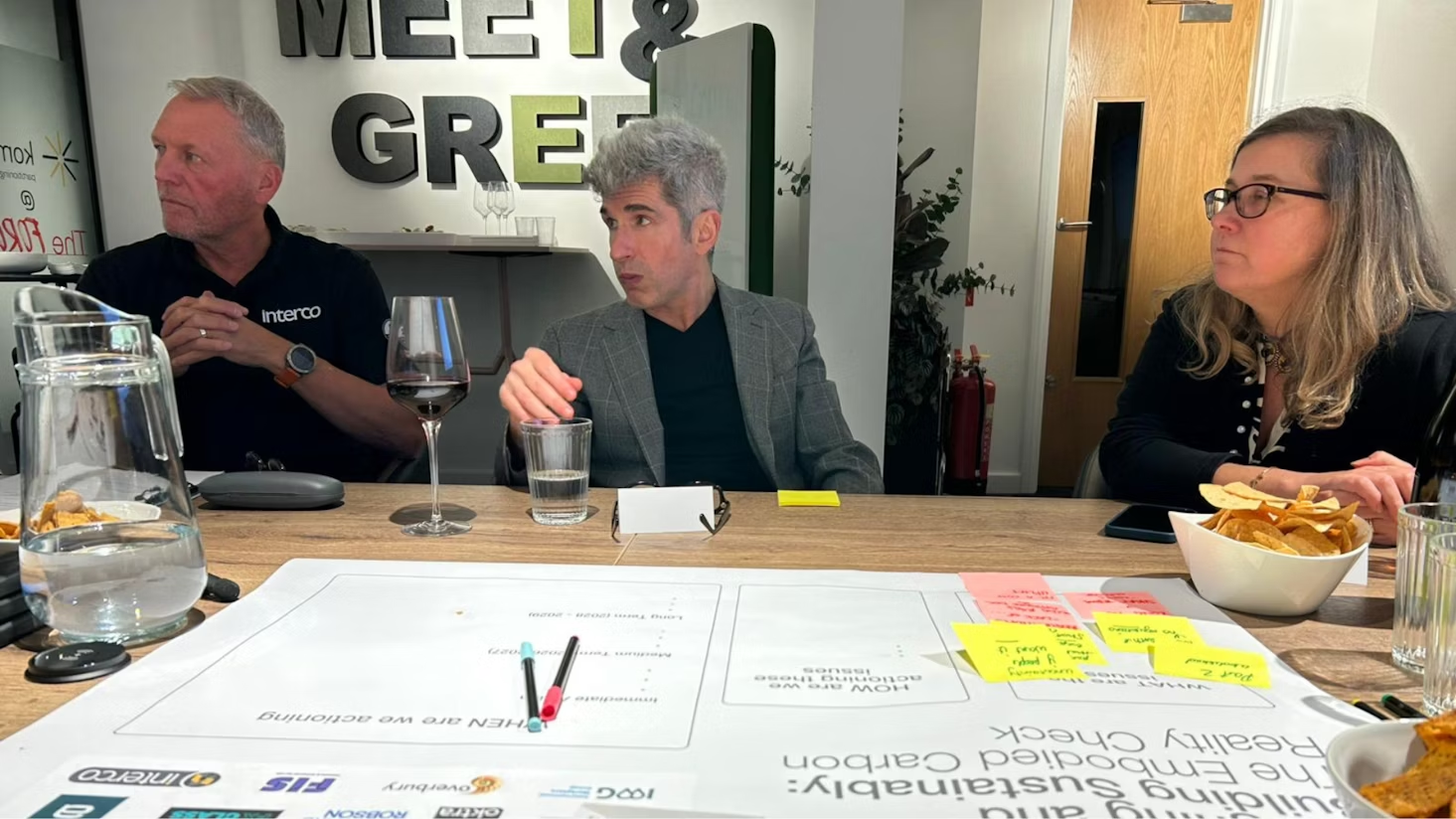

Komfort Partitioning hosted a collaborative roundtable on October 16th to address the practical, economic and systemic barriers to achieving Net Zero in the commercial fit-out sector. The discussion, framed by the core principle of Collaboration over Competition, brought together key leaders from across the design, manufacturing and construction sectors.

The resulting White Paper, “Designing & Building Sustainably: The Embodied Carbon Reality Check” outlines critical findings, challenges and actionable strategies for accelerating the transition to a circular economy.

The event brought together unique and often contrasting viewpoints to achieve a holistic understanding of the circular economy challenge:

- Enrique Soler (Area)

- James Semark (FX Glass)

- Flavie Lowres (The FIS)

- Prasun Bandyopadhyay (IWG)

- Tony Roberts (Interco)

- Steven Coveney, Paul Wyatt & Suzanne Walter (Komfort Partitioning)

- Jenny Edwards (Oktra)

- James Ivin (Overbury EOS)

- Armand Terruli (Sheppard Robson)

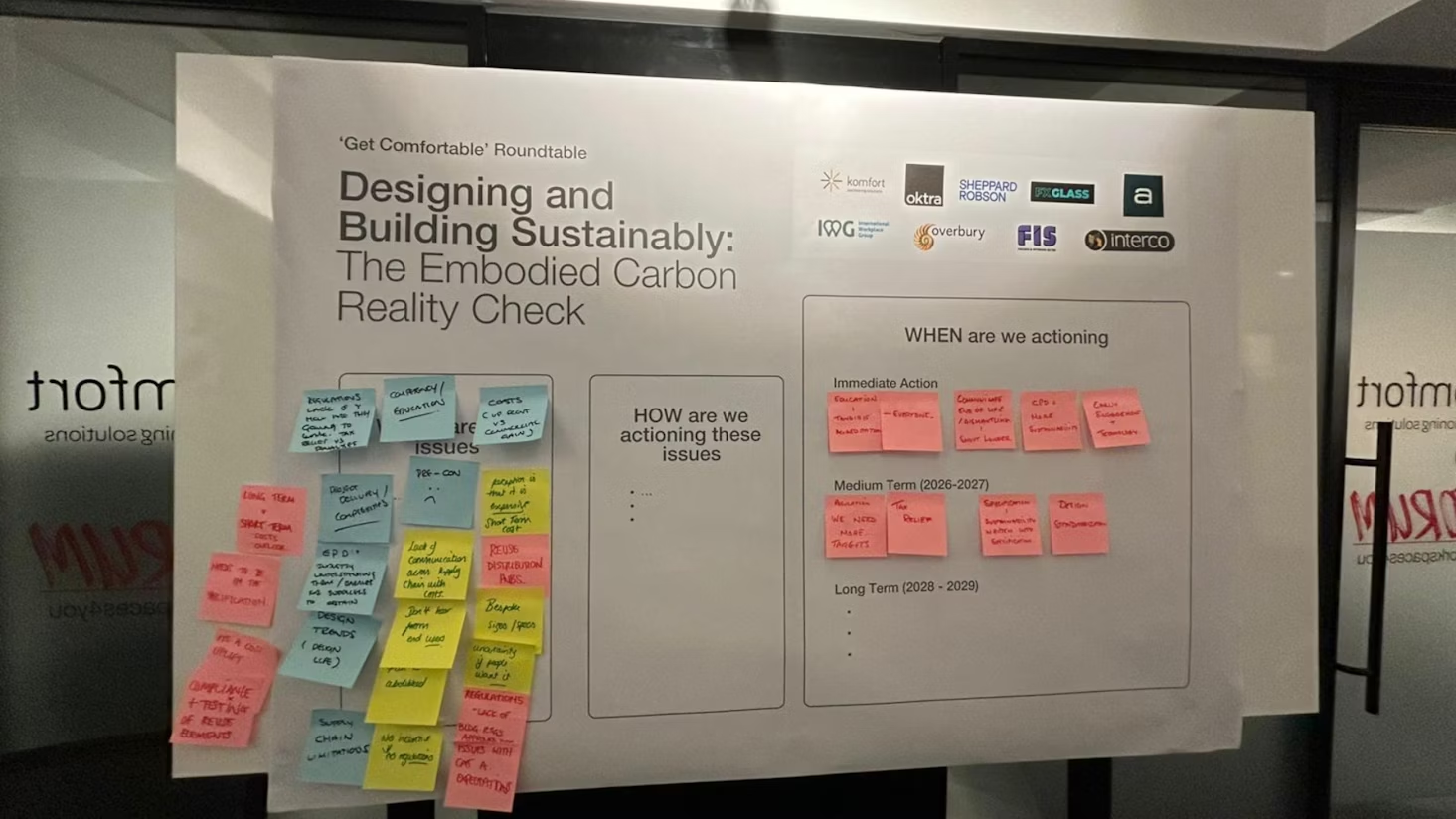

Core Challenges Identified

The discussion navigated three major systemic obstacles to achieving circularity:

1. Supply Chain & Market Readiness

- Demand for low-carbon material currently massively outstrips the supply of recycled content and certified relocatable systems.

- The risk of “greenwashing” remains high, necessitating verifiable data and transparency in environmental claims.

2. Business Model & Client Prioritisation

- The economic model is inverted: the donor (stripping out material) bears the financial burden of reuse (strip-out, logistics), disincentivising circular practices.

- Sustainability is often an afterthought; it must be driven by designers and architects through early engagement with partners.

3. The Lack of Regulation and Incentive

- The absence of mandatory regulation leads to inconsistent application and removes the incentive for contractors to change practices.

- The persistent perception that sustainable specifications are expensive is compounded by a lack of transparency regarding total value across the supply chain.

Action Points and Strategies

The White Paper provides a clear set of actionable recommendations across different levels of the industry, moving beyond “ideas” to produce concrete outcomes:

1. Policy, Legislation and Financial Incentives

- Lobby for Tax Relief: Lobby the government for tax relief for clients who specify and invest in demountable and relocatable partitioning systems.

- Mandatory Targets: Implement mandatory sustainability targets into building regulations and planning laws (similar to CDM).

- Financial Measures: Introduce measures like a carbon tax on high-carbon projects and offer tax breaks (like the R&D credit) for smaller companies using sustainable products.

2. Data, Standardisation and Design

- Update Specifications: Mandate key circular economy principles, including Cradle to Cradle certification and Design for Disassembly (DfD) requirements.

- Solve Logistics: Create robust logistics and storage protocols for reusable materials, such as ensuring glass partitions are stored correctly to remain viable.

- Establish Reuse Hubs: Collaborate to establish viable reuse distribution hubs to increase the supply of quality, tested reclaimed materials.

- Enforce Competency: Assess and demonstrate competency across the entire delivery chain through shared competency files during the tender process.

3. Education, Culture and Knowledge

- Drive Education: Implement a standardised approach to education to ensure all individuals possess the necessary skills, knowledge, and experience to deliver sustainable projects.

- Mandate CPD Inclusion: Professional bodies must mandate that every Continuing Professional Development (CPD) session includes a “sustainability strap” to build foundational knowledge.

- Earlier Engagement: Manufacturers and supply chain partners should be engaged earlier in the design process to better inform material choice.

A Call to Decisive Action

The reality check successfully achieved its goal of confronting the systemic barriers to Net Zero. The conversation affirmed that the desire for real change exists across the entire supply chain. Komfort Partitioning is committed to implementing these findings and will host future roundtables to revisit these action points and hold the industry accountable for delivering tangible, measurable results.

We would like to thank all participants of the roundtable for their contributions and support; we are already looking forward to the next one!